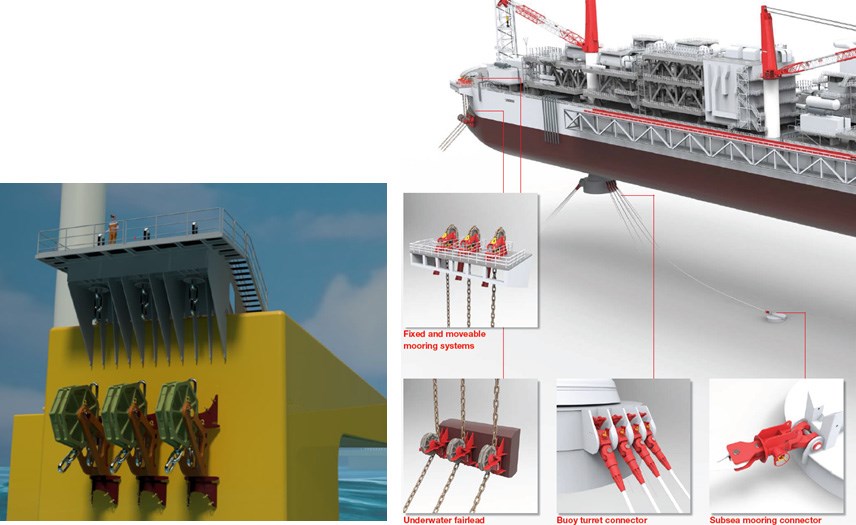

R&D, Manufacturing, and EPC of Floating Wind Power Mooring Systems (Introduction)

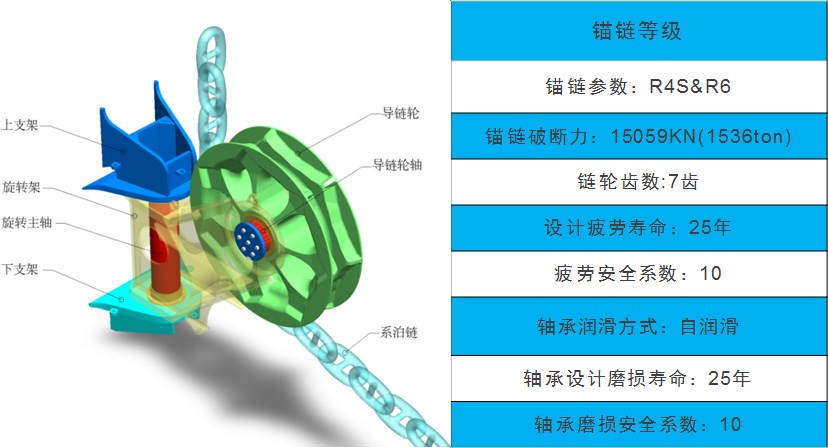

Constrain the movement displacement of the mooring anchor chain to ensure that it remains within the design allowable range under various harsh working conditions, thereby avoiding major accidents such as overloading and excessive wear of the anchor chain in the mooring system, and ultimately ensuring the safety of the entire floating platform.

R&D, manufacturing, and EPC (preliminary foundation) of floating wind power mooring systems

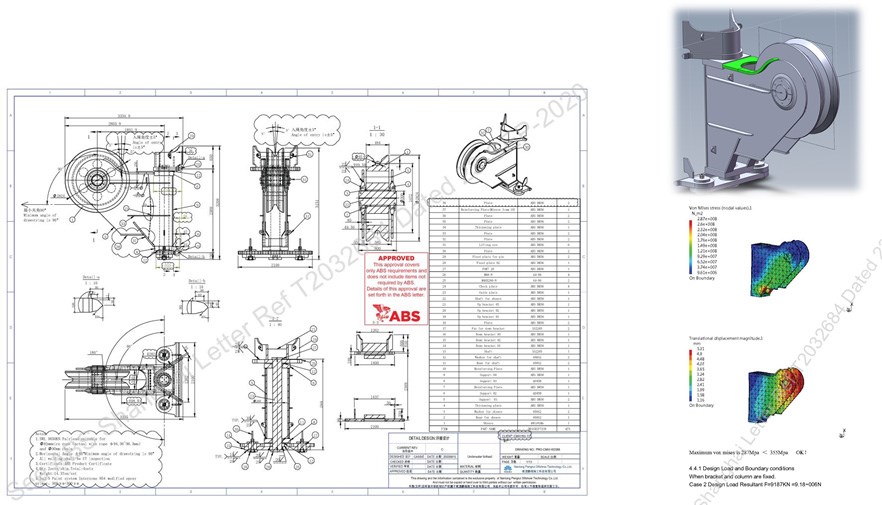

The small breaking force product developed by the project team has been approved and delivered for use by ABS classification society.

The project team, based on previous technological accumulation, has developed a breakthrough force by optimizing core technologies

The product has obtained recognition from the classification society

R&D, manufacturing, and EPC (preliminary foundation) of floating wind power mooring systems

The small breaking force product developed by the project team has been approved and delivered for use by ABS classification society.

The project team, based on previous technological accumulation, has developed a breakthrough force by optimizing core technologies

The product has obtained recognition from the classification society

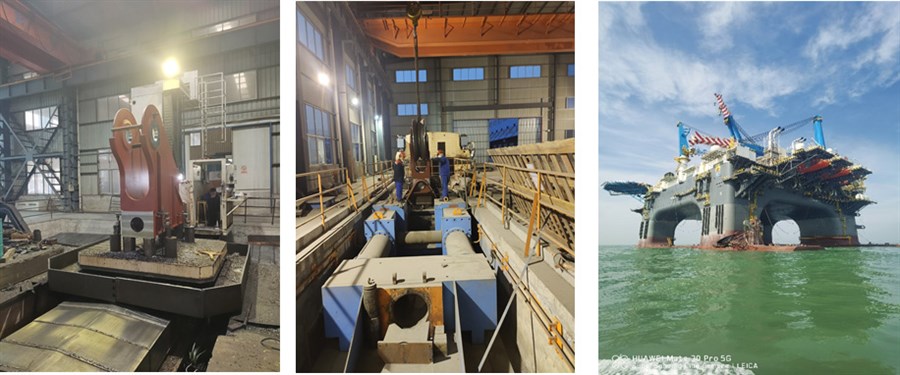

R&D, Manufacturing, and EPC of Floating Wind Power Mooring Systems (Currently Working)

Design priority, typical customized product solutions

Can be customized according to customer needs

Each project is designed separately

Design rejection by classification society

Design Fundamentals

Technical requirements for customer projects+classification society standards

Usage area+working conditions+design life (fatigue life verification)

Mooring anchor chain specification grade breaking force

Other requirements

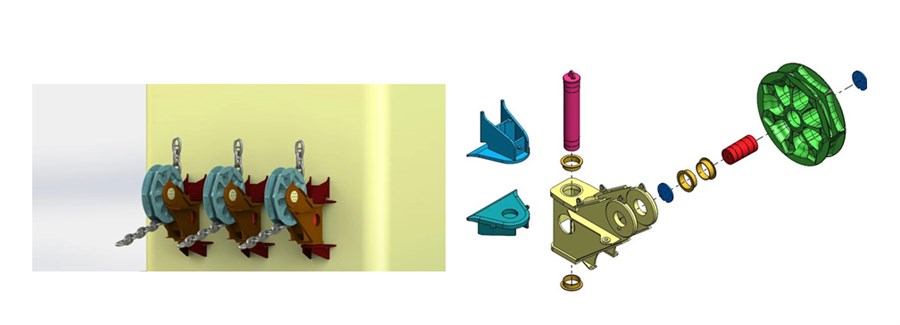

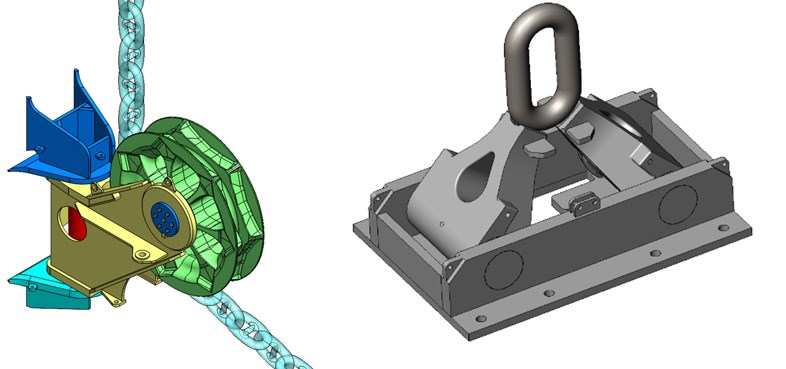

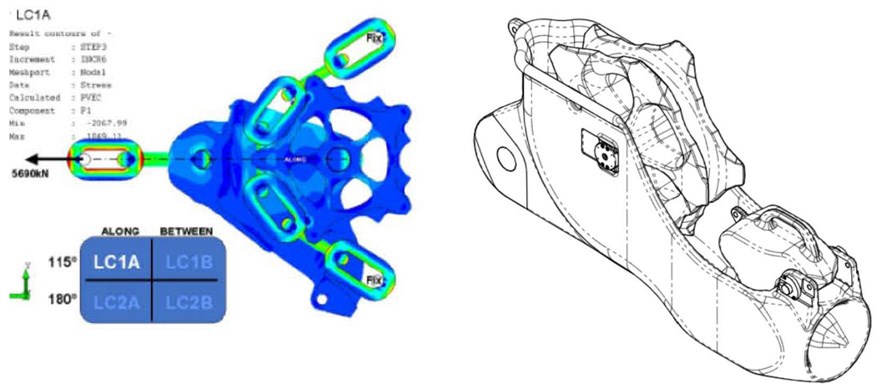

Chain stopper+chain guide connection scheme

Compared to the traditional oil and gas platform "anchor&chain stopper&chain guide" scheme, it can reduce the number of anchor machines.

By setting guide chain holes, the end of the anchor chain can be tensioned by pulling it with AHTS or by directly lifting the end of the anchor chain with a heavy crane.

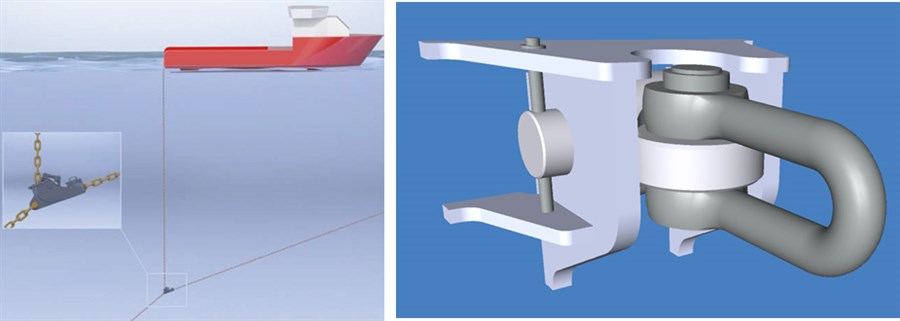

Universal joint+tensioner connection scheme

The tensioner has functions such as "tensioning&guiding chain&stopping chain", and is connected to the anchor chain at both ends without occupying the space of the ship.

Compared to the traditional oil and gas platform's "anchor machine&chain stopper&chain guide" solution, it is more economical.

R&D, Manufacturing, and EPC of Floating Wind Power Mooring Systems (Current Progress)

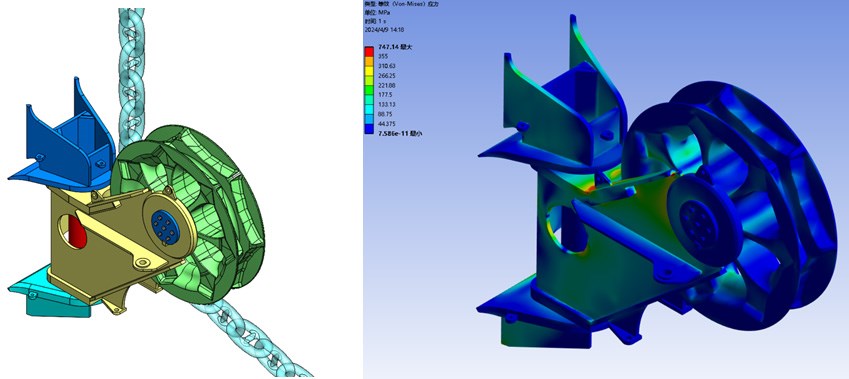

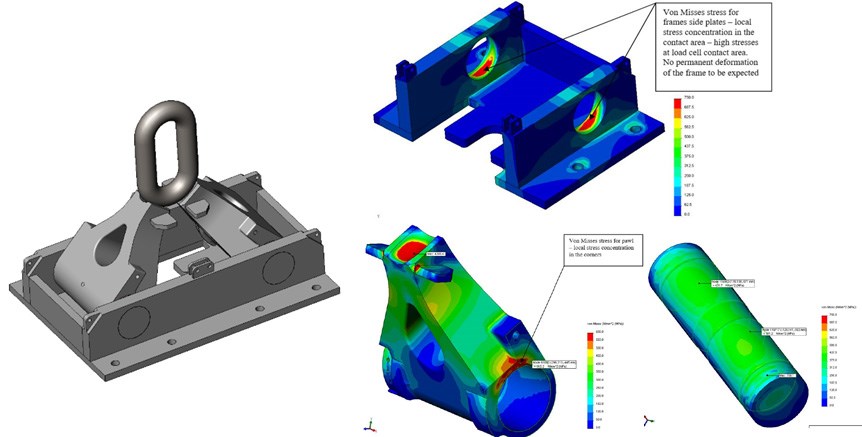

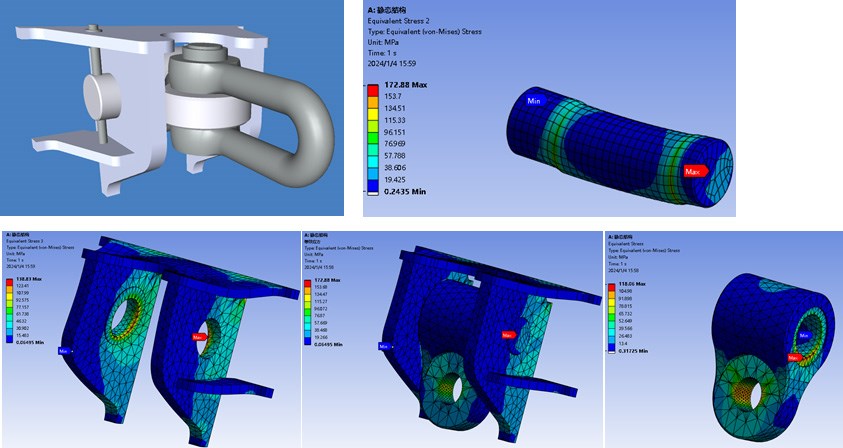

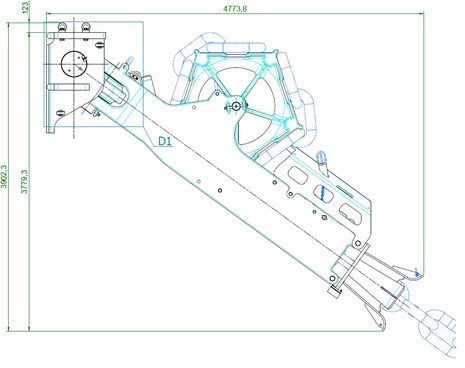

Schematic diagram of finite element analysis related to 1500ton breaking force chain guide.

R&D, Manufacturing, and EPC of Floating Wind Power Mooring Systems (Next Stage Tasks)

The overall installation plan for the integrated fairlead anchorage also needs to be upgraded accordingly

Collaborate with relevant floating platform manufacturers to provide a comprehensive EPC&Installation solution

Torpedo anchors are currently mainly used for anchoring designs at depths above 100m

Special design is required for torpedo anchors with a water depth of 50-100m for floating wind power projects to achieve the release of kinetic energy

Regarding the lowering of torpedo anchors, AHTS three purpose tugboats will also be upgraded accordingly